Stainless steel cutlery is everywhere, but have you ever wondered how it’s made? The process involves multiple steps, advanced machinery, and precise craftsmanship to achieve the perfect balance of durability and aesthetics.

Stainless steel cutlery is made through a detailed manufacturing process involving metal selection, shaping, heat treatment, polishing, and quality control. These steps ensure strength, corrosion resistance, and a sleek finish.

Understanding how stainless steel cutlery is made helps buyers appreciate the effort behind each piece. Let’s break down the entire process, from raw materials to finished products.

Table of Contents

How is stainless steel cutlery made?

Stainless steel cutlery is crafted using specialized processes, ensuring durability and a polished appearance. From raw material selection to final polishing, every step plays a crucial role.

Stainless steel cutlery is made through forging, stamping, heat treatment, and finishing techniques. These steps ensure durability, resistance to rust, and a polished, attractive surface.

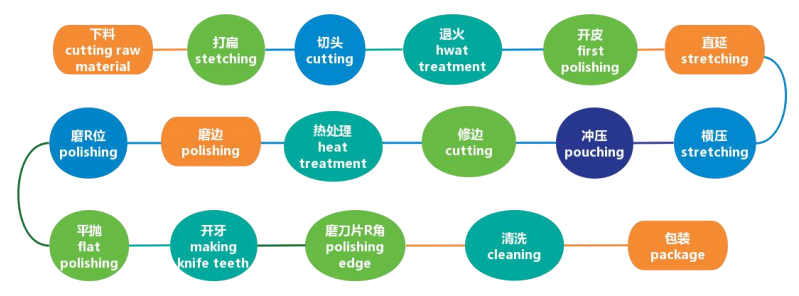

The Key Steps in Manufacturing Stainless Steel Cutlery

Manufacturing stainless steel cutlery is a complex process that combines precision engineering, metallurgy, and advanced finishing techniques. Each step plays a crucial role in determining the final quality of the product.

| Step | Description |

|---|---|

| Material Selection | High-quality stainless steel is chosen based on durability, resistance to corrosion, and ease of manufacturing. Common grades include 18/10 (18% chromium, 10% nickel) for high-end cutlery. |

| Cutting & Shaping | Stainless steel sheets or rods are cut into blanks using industrial cutters. Blanks are then stamped, forged, or pressed into rough shapes of forks, knives, and spoons. |

| Heat Treatment | The metal is heated to high temperatures (usually above 1000°C) and then rapidly cooled to enhance hardness, wear resistance, and flexibility. |

| Grinding & Polishing | Edges are refined to remove burrs, and surfaces are polished using abrasives and buffing wheels to achieve a mirror-like finish. |

| Quality Control | Each piece undergoes strict inspection for consistency, defects, and performance. Tests may include corrosion resistance, strength assessment, and surface quality checks. |

Each of these steps is carefully optimized to produce durable, aesthetically pleasing cutlery that meets industry standards.

What is the process of making cutlery?

The process of making cutlery is a precise combination of metallurgy, mechanical shaping, and finishing techniques. Every stage refines the product to ensure durability, design accuracy, and a flawless finish.

The cutlery-making process includes blanking, shaping, heat treatment, grinding, polishing, and quality checks. Each step enhances the product’s performance and aesthetics.

Exploring Each Stage in Detail

The manufacturing process follows a structured sequence to transform raw metal into finished cutlery.

Metal Blanking

Large stainless steel sheets or rods are cut into smaller blanks using hydraulic presses or laser cutters. These blanks define the rough shape of the cutlery pieces.Shaping

Depending on the method used, blanks are either pressed into molds (stamping) or hammered into shape (forging). Forged cutlery is generally thicker and more durable than stamped cutlery.Heat Treatment

The shaped cutlery is heated in a controlled furnace to a high temperature, typically around 1050°C, and then rapidly cooled in water or oil (quenching). This step improves hardness, flexibility, and wear resistance.Grinding and Finishing

Cutting edges (for knives) are sharpened using precision grinders, while forks and spoons are ground to remove excess material. Polishing is done using buffing wheels and abrasives to create a smooth, shiny surface.Final Inspection and Packaging

Each piece undergoes quality checks for dimensional accuracy, surface defects, and strength. Cutlery that meets the standards is cleaned, sometimes laser-engraved, and packaged for distribution.

Each of these steps ensures the final product is durable, functional, and visually appealing.

How is cutlery mass produced?

Mass production of cutlery relies on high-speed automation, advanced robotics, and precision engineering to ensure efficiency, uniformity, and cost-effectiveness.

Cutlery is mass-produced through automated stamping, heat treatment1, and polishing machines. This process enables large-scale production with consistent quality and minimal human intervention.

How Factories Ensure Efficiency in Mass Production

Factories optimize production using cutting-edge technology and streamlined workflows. The key elements of mass production include:

| Production Method | Benefits |

|---|---|

| Automated Stamping | Produces uniform blanks at high speed, reducing material waste and production time. |

| Conveyor-Based Heat Treatment | Ensures even hardening of the cutlery while maintaining precise temperature control. |

| Automated Polishing Machines | Achieves a consistent mirror finish with minimal manual labor, improving efficiency and reducing defects. |

| Laser Engraving | Enables precise customization of logos or patterns without compromising structural integrity. |

The Role of Robotics in Cutlery Manufacturing

In modern factories, robots play a vital role in streamlining production. Robotic arms handle precise movements in cutting, shaping, and polishing, ensuring uniformity and reducing human error.

What are the raw materials of stainless steel?

The quality of stainless steel cutlery2 depends on its raw materials.

Stainless steel is made from iron, chromium, and nickel, providing strength, rust resistance, and a smooth surface.

The Key Ingredients in Stainless Steel

| Element | Function |

|---|---|

| Iron | Provides the base structure of the alloy. |

| Chromium | Enhances corrosion resistance and durability. |

| Nickel | Adds strength and improves shine. |

The combination of these metals creates the stainless steel used in high-quality cutlery.

Is stainless steel expensive to manufacture?

The cost of stainless steel production depends on material quality, energy consumption, and processing techniques.

Stainless steel is more expensive than regular steel due to alloying elements like chromium and nickel, but its durability offsets the cost.

Factors Influencing Cost

- Material Costs – High-quality chromium and nickel increase the price.

- Energy Consumption – Melting and refining require significant energy.

- Manufacturing Techniques – Precision forging and polishing add to production costs.

Despite the higher initial cost, stainless steel’s longevity makes it a cost-effective choice over time.

What are the raw materials of cutlery?

Stainless steel cutlery starts with a precise mix of metals to ensure strength and longevity.

Cutlery is made from stainless steel, sometimes with added coatings or handles made of wood, plastic, or other materials.

Different Materials Used in Cutlery

| Material | Usage |

|---|---|

| Stainless Steel | Used for durability and corrosion resistance. |

| Silver | Found in luxury cutlery, offering a premium finish. |

| Plastic/Wood Handles | Added for grip and aesthetic appeal. |

The material choice depends on the cutlery’s intended use, cost, and target market.

What is the melting point of stainless steel?

Understanding stainless steel’s melting point is essential for processing and molding.

Stainless steel melts at approximately 1400-1450°C (2552-2642°F), allowing it to be shaped and hardened efficiently.

How the Melting Point Affects Manufacturing

High temperatures enable precise shaping and forging, ensuring durability. The melting point varies slightly based on the alloy composition, affecting how manufacturers handle it.

Is stainless steel 100% stainless?

While highly resistant to rust, stainless steel isn’t completely immune under extreme conditions.

Stainless steel is resistant to rust due to chromium, but prolonged exposure to harsh environments can cause corrosion.

When Stainless Steel Can Corrode

- Low Chromium Content – Cutlery with insufficient chromium may rust over time.

- Exposure to Harsh Chemicals – Strong acids can degrade the protective layer.

- Improper Maintenance – Failure to dry cutlery properly can lead to discoloration.

To maximize durability, high-quality stainless steel with proper care ensures long-term performance.

What are the 3 metals in stainless steel?

Stainless steel’s strength and rust resistance come from a specific metal combination.

Stainless steel is composed of iron, chromium, and nickel, which together provide durability, corrosion resistance, and an attractive finish.

The Role of Each Metal

| Metal | Function |

|---|---|

| Iron | The base metal, providing structure and strength. |

| Chromium | Creates a protective oxide layer, preventing rust. |

| Nickel | Enhances corrosion resistance and adds a bright finish. |

This combination makes stainless steel the ideal material for cutlery.

Conclusion

Stainless steel cutlery undergoes a detailed production process, from raw material selection to mass production. Understanding this process helps buyers appreciate its durability, quality, and value.