Cutlery is an essential part of our daily lives, but have you ever wondered how it’s made in bulk for global distribution? Let’s take a deeper look.

Mass producing cutlery involves a series of steps, from selecting raw materials to shaping and finishing the final product. It’s a detailed process designed for efficiency and quality control.

In this article, we’ll explore the intricacies of how cutlery is produced at scale, diving into the raw materials, manufacturing techniques, and the standards that define high-quality products.

Table of Contents

What are the raw materials of cutlery?

The foundation of any great cutlery starts with the right material. But what makes a material ideal for cutlery? Let’s break it down.

Raw materials for cutlery vary, but stainless steel, carbon steel, and plastic are common choices. Stainless steel, in particular, stands out for its strength, resistance to rust, and durability.

The choice of raw material significantly impacts the overall quality of the cutlery. Below, I’ll focus on stainless steel, the most commonly used material, and evaluate its benefits and drawbacks.

Stainless Steel: The Most Common Material

Stainless steel is favored for its durability, resistance to corrosion, and versatility. It’s an alloy primarily composed of iron, chromium, and nickel, which gives it its resistance to rust and staining. When used in cutlery, it provides both aesthetic appeal and functionality, ensuring that the products last over time and maintain their shine.

However, there are different grades of stainless steel, and the specific grade used can affect the performance of the cutlery. Grade 304, for example, is highly resistant to corrosion but can be slightly less durable compared to higher-end grades. Grade 420, often used for budget cutlery, has good hardness but is more prone to rusting if not properly maintained.

Here’s a comparison table of different stainless steel grades used in cutlery manufacturing:

| Stainless Steel Grade | Key Features | Durability | Corrosion Resistance | Common Use |

|---|---|---|---|---|

| Grade 304 | High corrosion resistance, non-reactive | High | Excellent | Premium cutlery |

| Grade 420 | Good hardness, budget-friendly | Moderate | Fair | Budget cutlery |

| Grade 440 | Excellent wear resistance | Very High | Good | Premium knives |

In choosing the right material, manufacturers must balance cost with quality, considering factors like corrosion resistance, aesthetics, and the intended use of the cutlery.

How are spoons manufactured?

Have you ever wondered how spoons are shaped, from raw material to finished product? Let’s walk through the manufacturing process.

The spoon manufacturing process involves several steps, including forging, shaping, polishing, and finishing. It’s a combination of craftsmanship and technology that produces a high-quality spoon.

Manufacturing spoons, especially in bulk, involves high precision and different techniques depending on the material used. I’ll go into greater detail on the common processes involved, highlighting the different stages of production.

Step 1: Material Selection

Just like with other types of cutlery, the first step is to select the material. Stainless steel is the preferred choice due to its durability, resistance to rust, and ability to be polished to a smooth, shiny finish.

Step 2: Shaping the Spoon

Once the material is selected, the next step is to shape the spoon. This typically involves a forging process, where the material is heated and then pressed into a spoon shape using molds or dies. Alternatively, stamping can be used for mass production. For higher-end spoons, the process may involve a more detailed hand-finishing approach to create intricate designs.

Step 3: Polishing and Finishing

After shaping, spoons go through polishing and finishing to remove any imperfections and ensure a smooth surface. This is essential for both aesthetic and practical reasons—polished spoons are more resistant to tarnishing and are easier to clean.

Step 4: Quality Control

At this stage, each spoon is examined for defects such as uneven surfaces, cracks, or flaws in the design. Quality control is critical, as these imperfections can affect the spoon’s functionality and appearance.

Step 5: Packaging and Distribution

Once the spoons have passed quality checks, they are packaged and shipped to customers or retailers. Packaging is an essential aspect, ensuring that the product reaches the market in perfect condition.

Metal spoon manufacturing process

The journey from raw metal to a fully formed spoon involves more than just shaping. It’s a precise, multi-step process that ensures the end result is both functional and durable.

The metal spoon manufacturing process involves several stages, including casting, forging, and finishing. Each step is critical for achieving the desired strength, aesthetics, and functionality.

The manufacturing of metal spoons is intricate, and multiple techniques come into play. I’ll break down the different processes involved, from the initial casting to the final polishing.

Casting: Starting with the Right Form

Casting is a common method used in spoon manufacturing, especially for more complex designs. During casting, molten metal is poured into a mold, where it cools and solidifies into the shape of a spoon. This process is particularly useful for producing spoons with intricate details or patterns.

Forging: Strengthening the Spoon

Forging is another common technique, especially for mass-produced spoons. In this process, metal is heated until it becomes malleable, then shaped using mechanical presses or hammers. Forging increases the strength of the spoon and provides better resistance to wear and tear compared to casting.

Finishing: Adding the Final Touch

Once the basic shape is formed, spoons undergo finishing, which includes polishing, smoothing, and sometimes electroplating. The goal is to remove any rough edges and ensure a smooth, shiny surface. Some spoons are also coated with an additional layer of material to enhance their durability and appearance.

Here’s a quick comparison of casting versus forging:

| Process | Features | Advantages | Disadvantages |

|---|---|---|---|

| Casting | Metal poured into molds | Suitable for complex designs | Less durable than forged spoons |

| Forging | Metal heated and shaped with hammers or presses | Stronger, more durable | Less suitable for intricate designs |

What makes good quality cutlery?

What defines high-quality cutlery? Is it the materials used, the craftsmanship, or something else? Let’s dive into what truly makes cutlery stand out.

Good quality cutlery isn’t just about the material. It’s the balance of material, design, craftsmanship, and durability that makes a piece stand the test of time.

When discussing quality, we need to consider multiple factors that contribute to cutlery excellence. From the materials used to the craftsmanship behind the design, each aspect plays a vital role.

Material Quality

The material used plays a significant role in defining the quality of cutlery. Stainless steel is the most common and widely used material, but the quality of the steel can vary. Higher-quality stainless steel alloys are more resistant to corrosion and staining, ensuring longer-lasting performance.

Craftsmanship

Craftsmanship refers to how well the cutlery is made. A well-crafted spoon or knife should have a smooth finish, well-aligned edges, and a comfortable grip. Additionally, proper weight distribution is important for functionality. Heavy, poorly balanced cutlery can feel awkward in the hand, while light, well-balanced pieces are easier to use.

Durability

Durability is perhaps the most important factor when evaluating cutlery. High-quality cutlery should be resistant to corrosion, staining, and physical damage. This is why stainless steel with a high chromium content is often the material of choice.

Which metal is commonly used in the manufacture of cutlery?

When it comes to cutlery, certain metals are preferred for their strength, rust resistance, and ability to retain a sharp edge. Let’s explore the most common options.

When it comes to cutlery, certain metals are preferred for their strength, rust resistance, and ability to retain a sharp edge. Let’s explore the most common options.

The choice of metal impacts everything from durability to aesthetics. Let’s take a look at the pros and cons of the metals commonly used in cutlery.

Stainless Steel

Stainless steel is the gold standard in cutlery manufacturing. It’s strong, resistant to rust, and easy to maintain. It also comes in various grades, with higher-end grades offering superior corrosion resistance and strength.

Carbon Steel

While stainless steel is the most common, carbon steel is used in some high-end knives due to its ability to hold a sharp edge. However, carbon steel requires more maintenance to prevent rusting.

Silver and Other Metals

Silver is sometimes used for luxury cutlery, though it’s not as common as stainless steel. It’s soft compared to steel, so it requires more maintenance and care. Other metals, such as titanium, are occasionally used in specialized applications.

Here’s a comparison of some metals used in cutlery manufacturing:

| Metal | Key Features | Durability | Corrosion Resistance | Maintenance Requirements |

|---|---|---|---|---|

| Stainless Steel | Strong, rust-resistant, easy to clean | High | Excellent | Low |

| Carbon Steel | Sharp edge retention, durable | Moderate | Fair | High |

| Silver | Luxurious, shiny | Low | Poor | Very High |

What is the safest material for cutlery?

When it comes to safety, not all materials are created equal. So, what is the safest option for cutlery?

Stainless steel is the safest material for cutlery due to its non-reactive nature and ability to withstand high temperatures without leaching harmful substances.

Safety is a top priority when choosing materials for cutlery. Let’s discuss why stainless steel is often considered the safest option.

Non-Reactive and Non-Toxic

One of the biggest advantages of stainless steel is that it’s non-reactive. This means it won’t leach harmful chemicals or react with acidic foods, making it safe for everyday use.

High Temperature Resistance

Stainless steel can also withstand high temperatures without warping or releasing toxins, making it safe for both hot and cold food preparation.

Other Materials

While stainless steel is the safest choice, there are other materials that can also be safe when used appropriately. For instance, titanium is non-reactive and incredibly strong, though it’s less commonly used in everyday cutlery.

What is most cutlery made of?

When you pick up a piece of cutlery, what material do you think it’s made from? Let’s dive into the most common materials used in cutlery production.

Most cutlery is made from stainless steel, which is strong, durable, and resistant to rust. Other materials like carbon steel and plastic are used for specific types of cutlery.

The material choice is critical because it impacts both the quality and longevity of the cutlery. Let’s examine the most common materials used, and what makes them suitable for cutlery manufacturing.

Stainless Steel: The Go-To Material

Stainless steel is the most widely used material for cutlery. It’s known for its strength, resistance to corrosion, and ease of maintenance. Stainless steel also provides an aesthetic appeal due to its shiny surface. The key to its success is the addition of chromium, which gives stainless steel its rust-resistant properties.

However, there are various grades of stainless steel, and not all are created equal. For example, Grade 304 stainless steel, while highly resistant to corrosion, can be softer and more prone to scratches. On the other hand, Grade 420 is much harder, which makes it a good choice for knives but less resistant to rusting.

Here’s a comparison of the different stainless steel grades:

| Stainless Steel Grade | Key Features | Durability | Corrosion Resistance | Common Use |

|---|---|---|---|---|

| Grade 304 | High corrosion resistance, non-reactive | High | Excellent | Premium cutlery |

| Grade 420 | Good hardness, budget-friendly | Moderate | Fair | Budget cutlery |

| Grade 440 | Excellent wear resistance | Very High | Good | Premium knives |

Carbon Steel

Carbon steel is less common but used for certain high-end knives because it holds an edge better than stainless steel. However, it requires more maintenance, as it can rust quickly if not cared for properly.

Plastic

Plastic cutlery is often used in disposable settings. It’s lightweight and cheap, but it doesn’t offer the same durability or functionality as metal options.

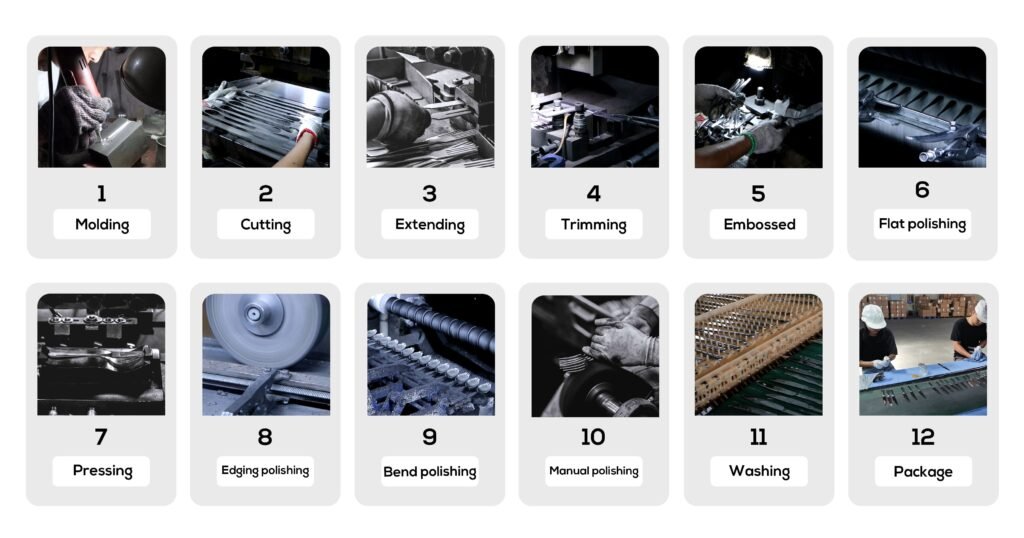

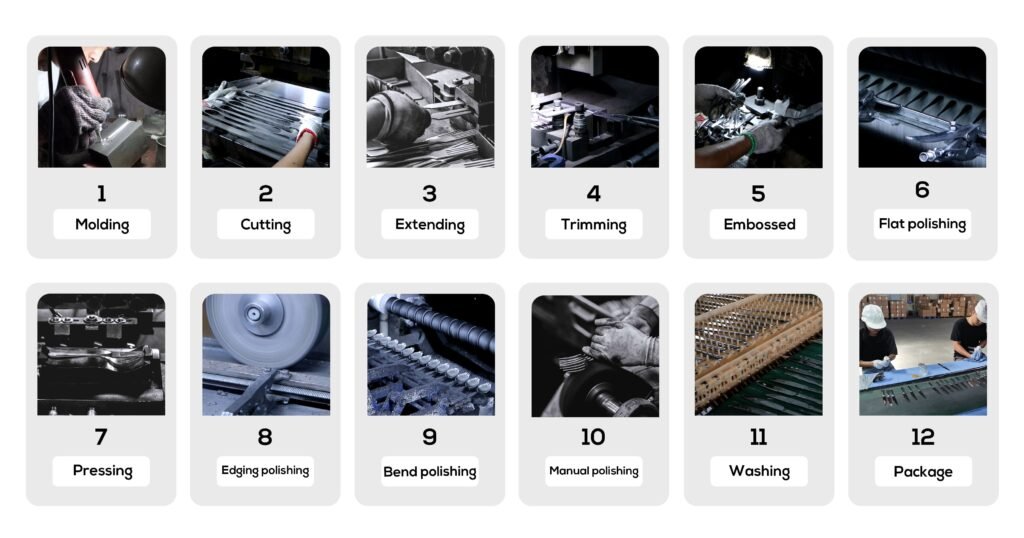

What is the process of making cutlery?

The process of making cutlery may seem straightforward, but it’s actually a combination of different methods that ensure quality and consistency.

The cutlery-making process involves several key stages, including shaping, polishing, and finishing. These steps vary depending on the material and type of cutlery being produced.

Creating cutlery is a detailed process, involving a few basic but critical steps. From selecting the right material to packaging the final product, each step ensures the cutlery performs well and lasts long.

Step 1: Material Selection

Choosing the right material is the first and most important step in cutlery manufacturing. Stainless steel, as discussed, is the most common choice, but manufacturers might use carbon steel for knives or plastic for disposable cutlery.

Step 2: Shaping the Cutlery

Once the material is chosen, it’s time to shape the cutlery. This involves processes like stamping, forging, or casting. For high-quality cutlery, forging is often preferred because it makes the metal stronger. The metal is heated until soft, then pressed into molds to form the desired shape.

Step 3: Polishing and Finishing

After shaping, cutlery is polished to remove rough edges and ensure a smooth finish. This step is essential for both aesthetics and functionality. The polish also helps prevent rusting and makes the cutlery easier to clean.

Step 4: Quality Control

Every piece of cutlery undergoes rigorous quality control checks to ensure it meets the required standards. This includes examining the finish, checking for any defects, and ensuring the strength of the material.

How are stainless steel forks manufactured?

Forks are one of the most commonly used pieces of cutlery, and making them involves specific techniques to ensure their durability and strength.

Stainless steel forks are manufactured using forging or stamping processes. After shaping, they undergo polishing and quality control before they’re ready for distribution.

Manufacturing stainless steel forks is a unique process that requires attention to detail. I’ll explain how each stage contributes to the creation of a durable and functional fork.

Step 1: Material Selection

Forks are typically made from stainless steel, as it’s durable, resistant to rust, and easy to maintain. The specific grade of stainless steel can vary, but Grade 304 is often used for premium forks due to its corrosion resistance.

Step 2: Shaping

The shaping process involves either forging or stamping. In forging, the metal is heated and shaped under high pressure. For mass production, stamping is more common, where a die is used to press the metal into the shape of a fork.

Step 3: Polishing

After shaping, the fork is polished to create a smooth, shiny surface. This step ensures that there are no rough edges that could hurt the user or impact the fork’s functionality.

Step 4: Quality Control

Before the forks are packaged, they go through quality control to ensure that each one meets the manufacturer’s specifications. This may include inspecting the finish, testing the fork’s strength, and checking for any defects in the metal.

What is flatware vs cutlery?

What’s the difference between flatware and cutlery? Many people use these terms interchangeably, but they actually have distinct meanings.

Cutlery refers to knives, forks, and spoons used for eating, while flatware typically refers to a broader range of table utensils, including serving dishes, bowls, and trays.

Flatware and cutlery are often confused, but understanding the difference between the two can be important for both manufacturing and usage. Let’s break it down.

Cutlery

Cutlery is the set of utensils specifically used for eating and preparing food. This includes knives, forks, spoons, and specialized utensils like seafood forks. Cutlery is designed for functionality, durability, and ease of use.

Flatware

Flatware is a broader category that encompasses cutlery but also includes other tableware like serving spoons, ladles, and even trays. Flatware is used for both serving food and eating it, while cutlery is strictly for eating.

Differences in Manufacturing

While both flatware and cutlery are often made from stainless steel, flatware can sometimes include more decorative pieces like serving platters. Cutlery, on the other hand, is more focused on practical design and functionality.

How do they mass produce knives?

Knives are one of the most challenging pieces of cutlery to produce. How do manufacturers ensure each one is sharp, strong, and ready for use?

Mass-producing knives involves forging or stamping, followed by grinding, sharpening, and polishing. The entire process ensures that the knives perform well and have a durable edge.

Manufacturing knives is a multi-step process that requires precision. Let’s dive into the stages involved in producing high-quality knives in large quantities.

Step 1: Material Selection

Knives are usually made from stainless steel or high-carbon steel. Stainless steel is favored for its corrosion resistance, while high-carbon steel is chosen for its ability to hold a sharp edge.

Step 2: Shaping

Knives are usually made using the forging method, where the steel is heated and hammered into shape. This process makes the blade stronger and more durable. For mass production, stamping is used, where a die presses the blade into shape.

Step 3: Grinding and Sharpening

Once the knife has been shaped, the blade is ground and sharpened to ensure a precise edge. This step is essential for ensuring the knife’s cutting performance.

Step 4: Polishing

The knife is polished to create a smooth, shiny surface. This also helps to prevent rusting and gives the knife a professional appearance.

What is the process of making silverware?

Silverware holds a special place in households and dining events. How is silver transformed into fine cutlery, though? It’s an intricate process that requires precision and artistry.

Making silverware involves a series of steps, including casting, forging, and polishing. The process is delicate, as silver is a soft metal that requires careful handling to create elegant and durable pieces.

The process of making silverware starts with selecting high-quality silver, usually in the form of ingots. The first step is melting the silver and casting it into molds to form basic shapes, like spoons, forks, and knives. Once the silver cools and solidifies, the pieces are forged to give them the desired thickness and texture.

Casting and Forging

Casting involves pouring molten silver into molds, shaping it into the rough outline of the cutlery. Afterward, forging enhances the durability and strength of the piece, especially for handles. The most common technique for this is die forging, where the cutlery is shaped by applying high pressure in a mold.

Polishing and Finishing

The final stages are polishing and finishing. Since silver tarnishes easily, it’s polished to a high shine using polishing compounds. Some silverware also undergoes an additional step of electroplating to enhance its resistance to tarnishing and improve its appearance.

| Step | Description |

|---|---|

| Casting | Molten silver is poured into molds. |

| Forging | High pressure shapes the pieces. |

| Polishing | Pieces are polished to a smooth finish. |

| Electroplating | Some silverware undergoes electroplating to add a protective layer. |

How is sterling silver flatware made?

Sterling silver flatware is a premium product known for its elegance. But how exactly do manufacturers turn raw silver into sterling flatware? Let’s break it down.

Sterling silver flatware is made by combining pure silver with other metals, then shaping, forging, and polishing it. The process ensures durability while preserving the natural beauty of the silver.

Sterling silver is an alloy made of 92.5% pure silver and 7.5% of another metal, usually copper. This combination gives the silverware strength while maintaining its aesthetic qualities. The process starts by melting the silver alloy and casting it into billets, which are long, solid pieces used as the base for shaping the flatware.

Shaping and Forming

After the billets are cooled and solidified, they are cut into smaller pieces and shaped into the desired forms using a combination of stamping and forging techniques. For example, the handles of forks and knives are often stamped to ensure uniform thickness.

Polishing and Detailing

Sterling silver flatware undergoes a series of polishing processes to achieve the desired smooth finish. Additionally, details such as engraving or decoration are often applied at this stage. The final product is polished to a high sheen to highlight the beauty of the silver.

| Step | Description |

|---|---|

| Alloying | Silver is mixed with copper to form sterling silver. |

| Casting and Shaping | Billets are melted, cast, and formed into flatware. |

| Polishing and Detailing | Final touches are added to enhance aesthetics. |

How is stainless steel cutlery made?

Stainless steel is a popular material for cutlery due to its strength and resistance to rust. But how is stainless steel transformed into the cutlery we use daily?

The process involves selecting stainless steel, followed by stamping, forging, and polishing. Stainless steel’s resistance to corrosion and durability make it a preferred choice for mass production.

Stainless steel cutlery is made from an alloy of steel that contains chromium, which makes it resistant to rust and tarnishing. The manufacturing process starts with stainless steel sheets or bars, which are cut into blanks, the rough shapes of forks, spoons, or knives.

Stamping and Forging

The blanks are then stamped into their final shapes using large machines, a method that ensures uniformity and mass production efficiency. After stamping, some pieces may be forged to improve strength and durability, especially for high-quality lines.

Polishing and Finishing

The final stage in making stainless steel cutlery is polishing. Stainless steel is known for its sleek, modern finish, and it requires polishing to remove any imperfections and create a smooth surface. Some cutlery may also undergo a brushing process to give it a matte finish.

| Step | Description |

|---|---|

| Alloying | Chromium is added to steel for durability. |

| Stamping and Forging | Blanks are stamped or forged into shape. |

| Polishing and Finishing | Final polishing to ensure smoothness. |

What are the steps of making silver?

Silver is one of the most sought-after metals for cutlery, but how is it extracted and processed into the fine silver used in utensils?

Silver is extracted from ore, purified, and alloyed before being crafted into cutlery. The process involves mining, smelting, and refining the silver to ensure its purity.

The process of making silver begins with mining silver ore, which is typically found in combination with other metals. The ore is then crushed and heated to extract the silver, a process known as smelting. Once the silver is separated from other metals, it is refined to achieve the desired purity.

Refining and Alloying

After the smelting process, the silver undergoes a refining process where it is purified to remove any impurities. Once purified, the silver can be alloyed with other metals to form sterling silver or other types of silver alloys, which provide the right balance of strength and malleability for cutlery.

Shaping and Finishing

Once the silver is refined and alloyed, it is cast into billets, which can be further shaped into spoons, forks, and knives. The silver is polished to create a high-quality finish, ensuring that it is both beautiful and durable.

| Step | Description |

|---|---|

| Mining and Smelting | Silver ore is mined, then smelted to extract silver. |

| Refining | The silver is purified to achieve high purity. |

| Alloying and Shaping | Silver is alloyed and shaped into cutlery. |

What is the process of making a fork?

A fork is an essential tool at any meal, but how exactly is it made? Let’s go through the steps in its creation process.

Making a fork starts with selecting metal, followed by stamping or forging it into shape. Polishing ensures a smooth finish before it’s ready for use.

The process of making a fork starts with choosing the right material, often stainless steel, due to its strength and rust resistance. The material is cut into blanks, and these are then stamped into the shape of a fork using large machines. After stamping, the forks may be forged to add extra durability to the tines.

Shaping and Forging

Once the blank is stamped, it is subjected to heat and pressure to improve its form and strength. The tines of the fork are carefully shaped, and the handle is elongated to ensure comfort.

Polishing and Finishing

The fork is then polished to ensure that it is free of sharp edges and has a smooth, clean surface. A final inspection is done to check for any defects, and once approved, the fork is ready for packaging.

| Step | Description |

|---|---|

| Material Selection | Stainless steel is selected for strength and durability. |

| Stamping and Forging | The fork is shaped and forged into its final form. |

| Polishing and Finishing | Polished to remove imperfections and ensure smoothness. |

What are the benefits of stainless steel spoons?

Stainless steel spoons are among the most popular cutlery choices. But why exactly do we favor them over other options? Let’s explore the reasons behind their widespread use.

Stainless steel spoons are durable, rust-resistant, and easy to clean. These qualities make them perfect for daily use, and their long lifespan saves money in the long run.

Stainless steel spoons are loved for many reasons, but let’s dig into why they stand out compared to alternatives like plastic or even silver. First, we need to consider the material’s resilience. Stainless steel is an alloy that includes iron, chromium, and sometimes nickel. This composition gives it a much stronger structure, which is why it’s not as easily bent or scratched as other materials. Furthermore, stainless steel resists rust and stains, which is crucial for cutlery used daily. When exposed to water or acidic foods, this material maintains its integrity without corroding, unlike iron, which can quickly rust.

Another key benefit is its non-reactivity. Stainless steel doesn’t interact with the food you eat. Unlike certain metals that can alter the flavor of your meal, stainless steel preserves the taste of food, ensuring an authentic experience every time you use it.

Cost-Efficiency

The cost-efficiency of stainless steel spoons cannot be ignored. Due to its durability, you won’t need to replace your cutlery as frequently. Over time, this saves money, making stainless steel a more budget-friendly option in the long run.

| Benefit | Explanation |

|---|---|

| Durability | Stainless steel is resistant to rust, corrosion, and wear. |

| Non-Reactivity | It does not affect the taste of food, keeping flavors pure. |

| Low Maintenance | Easy to clean and resistant to staining, requiring minimal care. |

What is the best metal for spoons?

When choosing the best material for spoons, several factors come into play. Let’s take a closer look at the top contenders and determine which metal stands out.

While there are several metals used in spoon manufacturing, stainless steel is often considered the best due to its strength, durability, and resistance to corrosion.

When selecting the best metal for spoons, we must evaluate factors such as durability, corrosion resistance, and cost. Stainless steel consistently outperforms other metals due to its unique blend of properties. While silver spoons are considered luxurious, they are soft, tarnish-prone, and require regular polishing. On the other hand, stainless steel is not only stronger but also resistant to stains and corrosion, which makes it a practical option for everyday use.

Aluminum is another common metal used for spoons, but it is less durable than stainless steel and can react with acidic foods, affecting the taste. Other metals, such as titanium, are lighter and stronger but come at a higher cost, making them impractical for mass production.

Key Factors to Consider

Choosing the right metal for spoons depends on the intended use. For daily use, stainless steel is ideal due to its resilience and low maintenance needs. For more decorative or ceremonial spoons, silver or even gold may be preferred for their elegance, but these materials are not as practical for everyday dining.

| Material | Corrosion Resistance | Strength | Ease of Maintenance | Cost |

|---|---|---|---|---|

| Iron | Poor | High | High | Low |

| Stainless Steel | Excellent | High | Low | Moderate |

Why is cutlery made of stainless steel rather than iron?

Iron was once a popular material for cutlery, but why has it been largely replaced by stainless steel? Let’s explore the factors that led to this change.

Stainless steel is favored over iron for cutlery because it resists rust and corrosion, unlike iron, which can degrade when exposed to moisture and acids.

Iron, despite its strength, has significant downsides when it comes to cutlery production. One of the main problems with iron is its susceptibility to rust. When exposed to water or acidic foods, iron begins to corrode, which makes it unsuitable for daily use. In contrast, stainless steel is composed of iron, chromium, and sometimes nickel. Chromium, in particular, plays a crucial role in forming a protective layer on the surface of stainless steel that prevents rust and corrosion, even when exposed to water and acidic foods.

Additionally, stainless steel offers better strength and durability. Iron can be brittle, especially when not alloyed with other metals, while stainless steel maintains its structural integrity under everyday stress. For mass production, stainless steel is also easier to mold and shape, allowing manufacturers to create a wide range of cutlery designs and sizes.

Longevity and Practicality

Stainless steel’s longevity is a major factor in why it’s preferred over iron. It doesn’t need as much maintenance or care, making it a more practical option for consumers and manufacturers alike.

| Material | Corrosion Resistance | Strength | Ease of Maintenance | Cost |

|---|---|---|---|---|

| Iron | Poor | High | High | Low |

| Stainless Steel | Excellent | High | Low | Moderate |

Is a metal spoon better than a stainless steel spoon?

Metal spoons can be made from various materials, but is stainless steel the best choice? Let’s compare the pros and cons of metal versus stainless steel spoons.

Stainless steel spoons outperform many other metal spoons due to their durability, rust resistance, and overall practicality, making them a top choice for everyday use.

When comparing metal spoons to stainless steel spoons, it’s important to recognize the various qualities each material brings to the table. First, stainless steel spoons are incredibly durable. Unlike some other metals, stainless steel resists rust, corrosion, and stains, making it ideal for everyday use. While other metals like aluminum may be lighter, they don’t provide the same level of strength or long-lasting performance.

One downside of stainless steel spoons, however, is that they can be heavier than some other metals, such as aluminum. While this is generally not a problem for most people, those looking for lighter utensils might prefer aluminum or plastic. However, these materials can easily be damaged or compromised with regular use, whereas stainless steel holds up over time.

Durability vs. Weight

The durability of stainless steel is one of its major selling points. While it may be heavier than some materials, it makes up for that weight with strength and resistance to damage, ensuring that your spoons last much longer than lighter, less durable metals.

| Disadvantage | Explanation |

|---|---|

| Weight | Stainless steel is heavier than materials like plastic and aluminum. |

| Scratching | It can develop scratches with heavy use or abrasive cleaning methods. |

| Environmental Impact | Production and recycling can have a higher environmental cost compared to others. |

What are the disadvantages of stainless steel cutlery?

While stainless steel cutlery is a popular choice, it’s not without its downsides. Let’s explore the disadvantages of using stainless steel for cutlery.

Despite its many advantages, stainless steel can be heavy, prone to scratching, and sometimes expensive. These factors can make it less ideal for certain uses.

While stainless steel offers many benefits, it’s not perfect for every situation. One of the biggest drawbacks is its weight. Stainless steel can be significantly heavier than other materials like plastic or aluminum. This can be a consideration for those who prefer lighter utensils, especially when preparing large meals or catering events.

Another disadvantage is that stainless steel can scratch more easily than some other materials, especially when used with harsh cleaning methods or abrasive surfaces. Over time, this can impact the appearance of the cutlery, even if its functionality remains intact.

Environmental Considerations

Though stainless steel is a durable material, it’s not as environmentally friendly as alternatives like bamboo or recycled plastics. The production of stainless steel requires a significant amount of energy, and its recycling process, while possible, isn’t as straightforward as that of other materials.

Stainless steel continues to be the go-to material for cutlery due to its durability, resistance to corrosion, and ease of maintenance. However, it’s not without its drawbacks, such as weight and potential scratching. The choice of material depends on individual needs and preferences.